Driving Momentum in Global Manufacturing

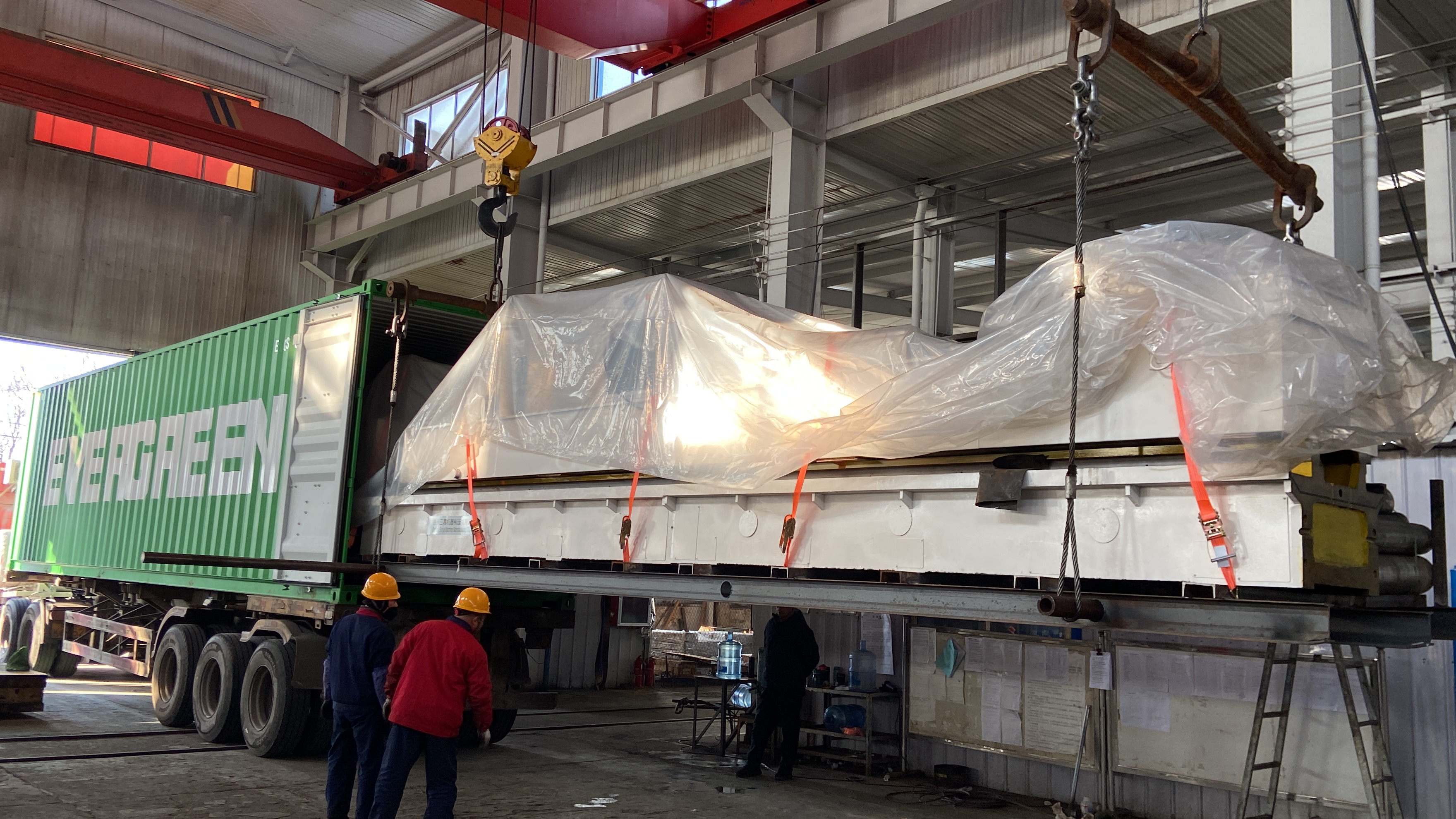

Today marks another milestone for our team as we successfully complete the final inspection and loading of two high-performance CNC machine tools. Watching these two heavy-duty machines leave our factory brings a sense of pride—not just because of the sale, but because we know they are about to boost productivity and precision for our client’s manufacturing line.

The two units shipped today are our signature models, engineered for rigorous industrial demands. Before leaving our assembly floor, they underwent continuous running tests to ensure optimal stability.

We believe that a machine tool is the “mother of industry.” Therefore, we never compromise on the core components or the assembly precision.

Shipping heavy machinery requires more than just a truck. It requires a systematic approach to packaging and logistics. To withstand long-distance ocean freight and potential humidity changes, our team implemented our standard export packaging protocol:

- Anti-Rust Treatment: All exposed metal surfaces are coated with professional anti-rust oil.

- Reinforced steel support: Fixed on the steel support, with internal and external reinforcement, to strictly prevent displacement during transportation.

This attention to detail ensures that when the customer unboxes the machine, it looks and performs exactly as it did on our factory floor.

Whether you need a standalone machine or a complete production line solution, we are here to provide the expertise you deserve. We thank our customers for their trust and look forward to seeing these machines in action!

Post time: Jan-04-2026